Load cells come in various categories, and here we will discuss one of their characteristics: explosion-proof (ATEX) capability.

In the previous article, we described different flammable and dusty environments, clarifying what each ZONE represents. Now, in this article, we intend to introduce load cells that can be used in these conditions for weighing systems.

To determine if a load cell is explosion-proof, you should first refer to its catalog to find out which ZONE it can be used in. Based on your needs and the load cell's installation environment, you can then select the appropriate model.

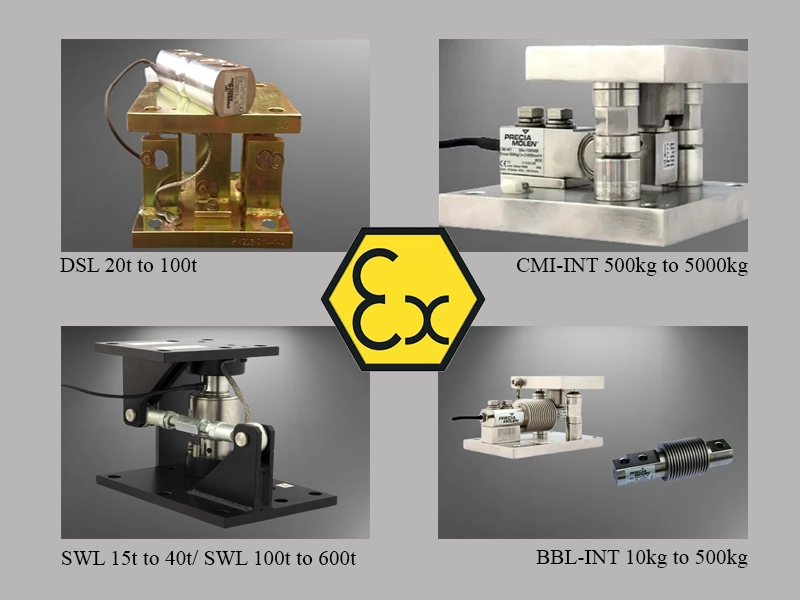

All load cells supplied by Pars Mavazin Company have ATEX capability. Some of them are listed in the table below:

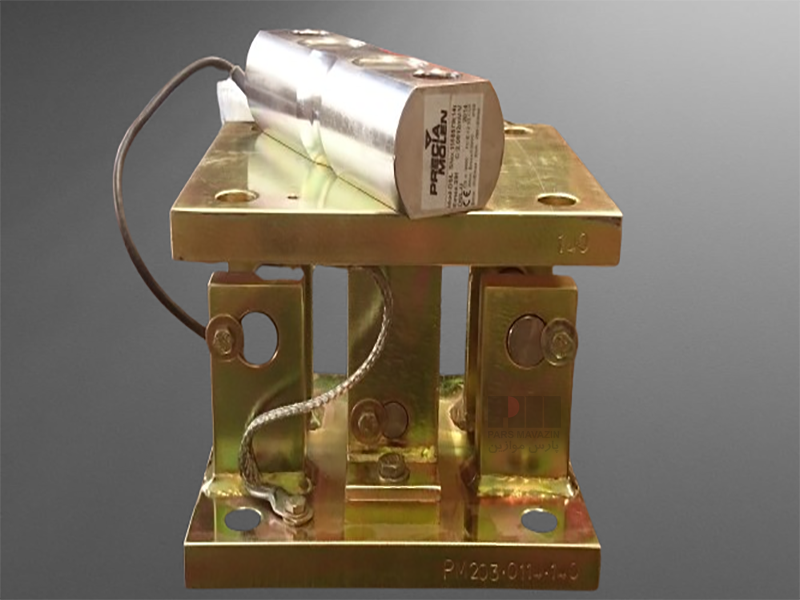

- DSL Shear beam load cell with a tonnage range of 20 to 100 tons

Zones 0 and 1 ......................... protection ia

Zone 2 ........................... protection ia or nA

Zone 20 , 21 ................... protection ta or ia

Zone 22 .......................... protection tc or ia

- CMI-INT Shear beam load cell with a tonnage range of 500 to 5000 kg

Zones 0 and 1 ......................... protection ia

Zone 2 ........................... protection ia or nA

Zone 20 , 21 ................... protection ta or ia

Zone 22 .......................... protection tc or ia

- BBL-INT Bending beam load cell with a tonnage range of 10 to 500 kg

Zones 0 and 1 ......................... protection ia

Zone 2 ........................... protection ia or nA

Zone 20 , 21 , 22 .................... protection tD

- SWL Compression load cell with a tonnage range of 15 to 40 tons / 100 to 600 tons

Zones 0 and 1 ......................... protection ia

Zone 2 ........................... protection ia or nA

Zone 20 , 21 .................... protection ta or ia

Zone 22 ......................... protection tc or ia

Here is a brief explanation of the protection types mentioned for each zone:

- Protection ia (Intrinsic Safety 'ia'):

- This is a type of Intrinsic Safety protection.

- "ia" provides the highest level of intrinsic safety. This means that even if two independent faults occur, these devices will not be able to produce sparks or heat sufficient for an explosion.

- It is suitable for use in Zone 0 (areas where an explosive atmosphere is continuously present or present for long periods) and Zone 20 (for dust, equivalent to Zone 0 for gases).

- Protection nA (Non-Sparking 'nA'):

- This type of protection is for equipment that, under normal operating conditions, is not capable of producing sparks or electrical arcs with enough energy to cause an explosion.

- It is suitable for use in Zone 2 (areas where an explosive atmosphere is unlikely to occur during normal operation, and if it does, it will only persist for a short period).

- Protection tD (Protection by Enclosure 'tD'):

- This type of protection is typically used for protection against combustible dust.

- "tD" stands for "Protection by Enclosure, 't'" for dust protection, and D indicates the equipment group.

- Protection 'ta' (Protection by Enclosure, 'ta'):

- This is the highest level of protection against dust.

- It is designed for use in Zone 20 (areas where combustible dust is continuously present or present for long periods).

- Protection 'tb' (Protection by Enclosure, 'tb'):

- This is a lower level than 'ta'.

- It is designed for use in Zone 21 (areas where combustible dust may be present during normal operation).

- Protection 'tc' (Protection by Enclosure, 'tc'):

- This is the lowest level of protection in this category.

- It is designed for use in Zone 22 (areas where combustible dust is unlikely to occur during normal operation, and if it does, it will only persist for a short period).